Surge Protection for Weigh Bridges

Weighbridges: Precision Scales for Heavy Loads

Weighbridges, also known as truck scales or platform scales, are essential tools in industries where accurate measurement of heavy loads is crucial. These large-scale weighing systems are designed to handle vehicles and cargo, providing precise weight measurements for various applications, including logistics, agriculture, and manufacturing.

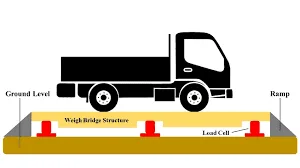

Platform

The platform is the most visible part of a weighbridge. It’s a robust, flat surface that vehicles drive onto for weighing. Platforms are typically made of steel or concrete and can vary in size to accommodate different vehicle types. Weighbridges are often installed in open, outdoor areas, making them especially vulnerable to lightning strikes. Consequently, lightning can cause devastating electrical surges that travel through power lines, communication lines, and grounding systems, causing significant damage to the weighbridge’s electronic components. Moreover, the sensitive load cells, sensors, and control systems that weighbridges rely on can be rendered useless if hit by a surge.

SPDs act as a critical first line of defense by diverting excess voltage away from these sensitive components. Properly installed SPDs prevent damage by grounding the surge, allowing the weighbridge to continue functioning without downtime or expensive repairs. Without these protections, a single lightning strike could lead to the loss of crucial operational time and high replacement costs.

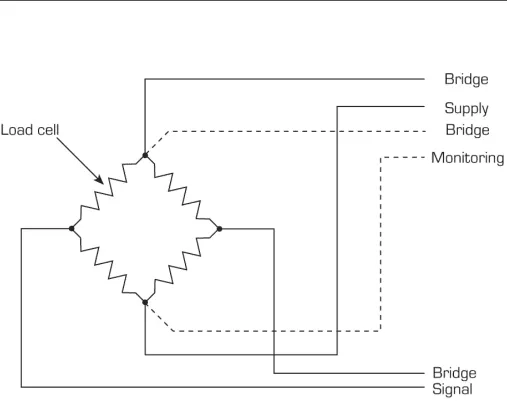

Load Cells

Load cells undoubtedly form the core of a weighbridge’s weighing system. These transducers effectively convert the force exerted by the weight on the platform into an electrical signal. Moreover, to ensure precise measurements, most modern weighbridges utilize multiple load cells, typically positioned at each corner of the platform. Consequently, this setup guarantees accuracy, regardless of how the load is distributed.

Common Types of Load Cells Used in Weighbridges

- Compression Load Cells: These load cells measure weight through compression, making them suitable for heavy-duty weighbridge applications.

- Shear Beam Load Cells: Ideal for applications requiring high accuracy, these load cells measure force in shear, ensuring precise weight readings.

- Double-Ended Shear Beam Load Cells: These load cells offer enhanced stability and accuracy, especially in weighbridges that handle heavy loads.

The Role of the Junction Box

The junction box is crucial for collecting signals from all the load cells and combining them into a single output. Additionally, it protects against environmental factors such as moisture and dust, ensuring the system’s longevity.

Digital Display Unit

Modern digital display units show accurate weight readings and often feature advanced capabilities like data storage, printing, and network connectivity, making them an essential component of weighbridge systems.

Structural Support Elements

- Beams: The beams offer structural support for the platform and transfer the weight from the platform to the load cells, ensuring accurate measurements.

- Foundation: Typically made of concrete, the foundation maintains the weighbridge’s stability and levelness, which is critical for precise weight readings.

Vehicle Access Ramps

Ramps enable vehicles to drive onto and off the platform easily. They are designed to withstand repeated use while maintaining the accuracy of the weighbridge.

LPES: A Trusted Leader in Lightning and Earthing Protection

Founded in 2012, LPES has completed over 100 industrial projects, establishing itself as a trademark in the industry. With vast experience and in-depth knowledge of industry standards, LPES offers superior lightning and earthing protection solutions for both commercial and industrial clients.

Compliance with Industry Standards

LPES products strictly adhere to renowned standards, including the International Electrotechnical Commission (IEC), Bureau of Indian Standards (BIS), French Standards (NFs), Underwriters Laboratories (UL), National Fire Protection Association (NFPA), and the Institute of Electrical and Electronics Engineers (IEEE). Consequently, these standards ensure that our products consistently meet the stringent requirements of various sectors, such as industrial, automotive, military, power, telecommunication, mining, aviation, marine, FMCG, and testing labs.

Commitment to Innovation and Quality

LPES truly stands out for its relentless innovation and continuous improvement. Moreover, by staying ahead in technology, we consistently provide superior solutions that effectively protect critical infrastructure from lightning strikes and electrical surges. Additionally, our transparent communication approach ensures that clients always receive detailed information about product specifications and installation processes.

This revised version maintains clarity, adds subheadings, reduces passive voice, and incorporates transition words for better readability and SEO optimization.

LPES Product Range and Expertise

Data Communication Protection: The LPESpatch series offers robust protection for RS 232, RS 485, and Ethernet data communication lines, ensuring uninterrupted and secure data transmission.

Voltage Protection: For DC voltage applications, the LPESguard series provides reliable protection for 24V supply systems.

Versatile Solutions: The LPESconnect and LPESductor series offer a wide range of products tailored to various applications, ensuring comprehensive protection solutions.

Why Choose LPES?

Successful project completions and positive customer feedback have helped LPES build a strong lightning and earthing protection reputation. Clients recognize our products for their superior effectiveness and lasting reliability. Each project demonstrates our commitment to delivering high-quality performance and durability, which our clients appreciate. Our extensive industry knowledge, ethical practices, and unwavering focus on customer satisfaction drive this success. As a result, LPES leads the way in providing reliable earthing and lightning protection solutions.

The Importance of Surge Protection for Weighbridges

Industries that rely on precise weight measurements consider weighbridges vital. However, electrical surges often expose these systems to serious damage, leading to costly downtime. Surge Protective Devices (SPDs) shield weighbridges from lightning strikes, power grid fluctuations, and voltage spikes. As a result, by installing SPDs, businesses protect their investments, maintain accuracy, and ensure operational efficiency. Moreover, electrical safety standards require firms to implement surge protection measures to safeguard both equipment and personnel. Additionally, national and international regulations demand that weighbridge operators install SPDs, making it essential for them to meet these safety standards.

Surge protection plays a crucial role in industries that depend on accurately measuring heavy loads. Weighbridges, commonly referred to as truck scales or platform scales, serve as essential tools in this context. Designed to handle vehicles and cargo, these large-scale weighing systems deliver precise weight measurements for various applications, including logistics, agriculture, and manufacturing. Furthermore, weighbridges are susceptible to electrical surges, which can cause significant damage and disrupt operations. Therefore, surge protection is vital to safeguard these critical assets and maintain their reliability.