Importance of Surge Protection Devices in Packaging Industry

Surge Protection Devices (SPDs) in the packaging industry are essential for safeguarding sensitive equipment. SPDs protect against transient overvoltages, ensuring continuous operations and preventing costly downtime. By diverting excess voltage, they help maintain product quality and prevent disruptions in production, making them a vital component in modern packaging facilities.

Introduction to SPDs in Packaging:

- Safeguarding Operations: SPDs shield critical equipment from voltage spikes, preventing production disruptions and ensuring product quality.

- Transient Overvoltages: Sudden voltage increases can damage sensitive electronics, but SPDs divert excess voltage to protect machinery.

- Continuous Protection: SPDs offer a round-the-clock defense, ensuring uninterrupted packaging operations and product integrity.

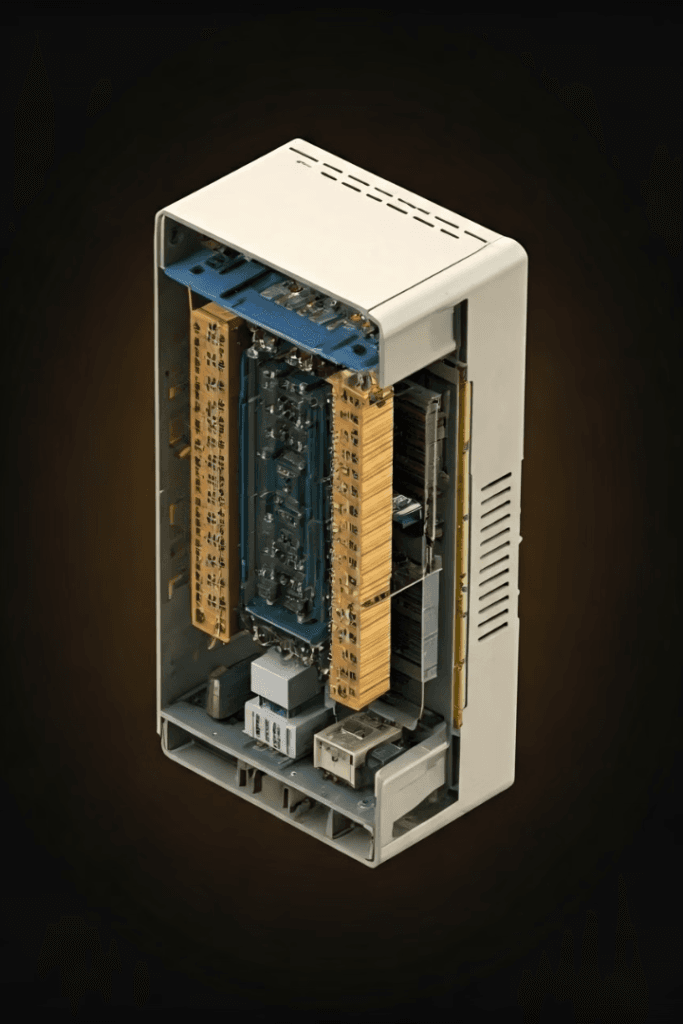

Understanding surge protection devices

Type 1 SPDs: installed at main distribution boards to protect against direct lightning strikes and severe surges.

Type 2 SPDs: Located at sub-distribution boards, handling induced surges and switching transients.

Type 3 SPDs: Positioned near sensitive equipment for fine protection against residual surges.

Critical areas requiring SPD protection

Main Power Distribution Room:

Prevents large surges from entering the facility.

Automation Control Room:

Protects PLCs and other automation devices.

Production Floor:

Protects packaging machinery from surges caused by motor startups.

Data Center:

Safeguards servers and networking equipment from data loss.

Risks of Inadequate Surge Protection:

Equipment Damage: Unprotected machinery is vulnerable to surges, leading to high repair costs.

Production Downtime: Failures lead to unexpected shutdowns, affecting deadlines and customer satisfaction.

Data Loss: Surges can corrupt production data, compromising quality control.

SPD Specifications for Packaging Facilities

| Area | Equipment | SPD Type | Uc (V) |

|---|---|---|---|

| Main Power Distribution Room | Switchgear | Type 1 | 320 |

| Automation Control Room | PLCs and Automation Devices | Type 2 | 320 |

| Production Floor | Packaging Machinery | Type 3 | 320 |

| Data Center | Servers and Networking Equipment | Type 3 | 320 |

Benefits of Implementing SPDs:

- Enhanced Protection: Robust defense against surges reduces equipment failure risk.

- Cost Savings: Reduces maintenance and replacement costs, extending equipment lifespan.

- Compliance: Ensures adherence to IEC 61643-11 and GB 18802.11 standards.

Implementing SPDs in Existing Facilities:

- Assess current setup: evaluate infrastructure and identify vulnerable points.

- Design Protection Scheme: Create a comprehensive SPD implementation plan.

- Install and Test: Professional installation and thorough testing verify protection.

- Regular Maintenance: Schedule inspections to maintain SPD effectiveness.

Future-Proofing with SPDs

Industry 4.0 Ready:

Guarantees the reliability of IoT and data

analytics systems.

Scalable Protection:

Modern SPDs evolve with facility

expansions.

Energy Efficiency:

Advanced SPDs optimize power

management.

Conclusion: Securing Your Packaging Operations with Surge Protection Devices (SPDs)

Comprehensive Protection: Surge Protection Devices (SPDs) are essential for shielding sensitive packaging equipment from unpredictable electrical surges, safeguarding crucial operational data, and ensuring continuity in production processes. Moreover, by mitigating the impact of transient overvoltages, SPDs prevent costly breakdowns and interruptions, thereby helping to maintain consistent production flow and high-quality output. Furthermore, their protective function extends beyond just machinery, consequently encompassing the entire production infrastructure to keep the facility running smoothly and securely.

Standard Compliance: Implementing SPDs underscores a commitment to safety and industry best practices. Moreover, by adhering to recognized standards like IEC 61643-11 and GB 18802.11, companies demonstrate dedication to operational excellence and compliance with global safety norms. Furthermore, these standards are crucial in regulated industries where reliable, high-quality production is key. Consequently, following these standards safeguard internal processes and instill confidence in clients, partners, and regulatory bodies, thereby reinforcing the organization’s reputation for reliability.

Long-Term Benefits: Investing in SPDs offers significant long-term advantages. Moreover, SPDs reduce equipment downtime by preventing surge-related failures, thereby leading to fewer unplanned maintenance interruptions and cost savings on repairs and replacements. Furthermore, this preventative approach enhances the lifespan of packaging machinery, automation control systems, and data centers, consequently contributing to overall operational efficiency. Ultimately, with a robust SPD system in place, businesses experience fewer production delays, improved equipment reliability, and lower operational costs—factors that are vital for staying competitive in the packaging industry.