Lightning and Surge Protection for Industrial Buildings

A well-managed factory or industrial building filled with costly production machines, computers, and other advanced technology can experience severe impacts from electrical disturbances. These buildings often fall victim to power surges or lightning strikes, which can cause significant disruption. For instance, a direct lightning strike to the building or its vicinity poses a major threat. Furthermore, lightning strikes on nearby services or infrastructure can quickly disrupt daily operations and even compromise the building’s structural integrity.

Power surges, often resulting from an overloaded transformer failure within the factory or a lightning strike, can cause catastrophic damage. As a result, we face the challenging and costly task of replacing all the damaged equipment, which may lead to even more serious consequences if not addressed promptly.

By understanding these risks, you can take proactive steps to protect your facility, ensuring that such electrical disturbances do not hinder your operations.

To avoid any damage to the structure, occupants, machinery, and people from direct lightning strikes, it is crucial to install a lightning protection system (LPS). An LPS comprises two main components: external lightning protection and internal surge protection. The International Electrotechnical Commission (IEC) standard 62305 provides comprehensive guidelines for designing and implementing lightning protection systems. Specifically, IEC 62305-3 focuses on external lightning protection, which aims to safeguard the structure from the devastating effects of a direct lightning strike.

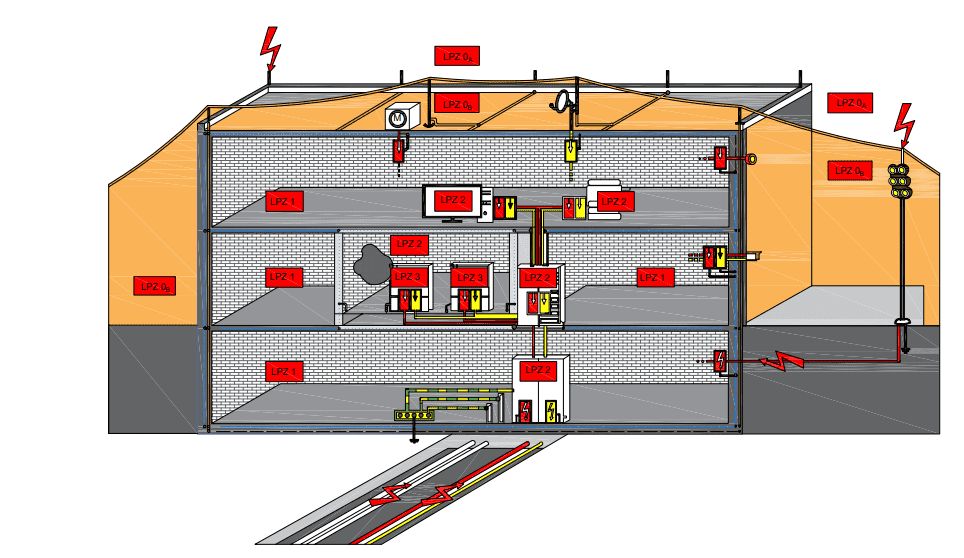

According to IEC, the Lightning Protection Zone (LPZ) defines the area where the electromagnetic environment is specified. This zone may not have a physical boundary.

LPZ OA zone where the threat is due to the direct lightning flash and the full lightning electromagnetic field. Full or partial lightning surge currents may affect the internal systems.

LPZ OB zone protected against direct lightning flashes but where the threat is the full lightning electromagnetic field. The internal systems may be subjected to partial lightning surge currents.

In LPZ 1, the surge current limits itself through current sharing and by isolating interfaces and/or SPDs at the boundary.

In LPZ 2 and subsequent zones, the system can further limit the surge current through current sharing. And isolating interfaces or by adding more SPDs at the boundary. Additionally, users can apply spatial shielding to further attenuate the lightning electromagnetic field.

Before installing a lightning protection system, it is crucial to first calculate the lightning protection level according to the IEC standard. This process involves a thorough assessment of the risks. And potential damages to the building from both direct and indirect lightning strikes. By accurately determining the lightning protection level, we can ensure that the installed system will. Provide adequate protection against lightning-induced hazards.

Once the lightning protection level has been confirmed, the next step is to install a lightning protection system along with surge protection to effectively safeguard the entire building and its occupants. LPES International has, over the years, established itself as a trusted leader in lightning and earthing protection, becoming renowned for its consistent focus on safety since its founding in 2012.

To date, we have completed over 100 industrial projects. With these projects, we have, indeed, made a significant mark in the industry. Thanks to our vast experience and in-depth knowledge of industry standards for lightning and earthing protection, LPES continues to provide top-tier products that meet the stringent requirements of both commercial and industrial clients. Moreover, we design our products with precision to ensure optimal performance, even in the most challenging environments. Additionally, our products adhere to standards such as the IEC (International Electrotechnical Commission), BIS (Bureau of Indian Standards), NF (French Standard), UL (Underwriters Laboratories), NFPA (National Fire Protection Association), IEEE (Institute of Electrical and Electronics Engineers), and many more. Consequently, these standards are widely utilized in various sectors, such as industrial, automobile, military, power, telecommunications, mining, aviation, marine, FMCG, testing labs, and more.

External Lightning Protection of Industrial Building-

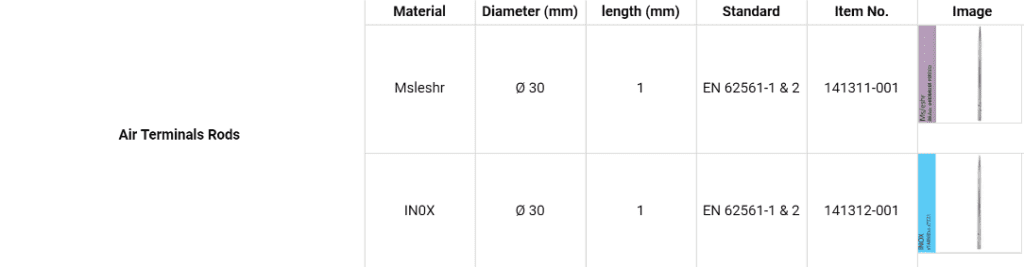

- Air Termination Method.

The standard specifies that an external LPS, utilizing metallic elements such as rods, mesh conductors, or catenary wires, should be strategically positioned to effectively intercept lightning flashes from all types of air-termination systems. Furthermore, the specific location and configuration of the LPS depend on the building’s height and lightning protection level. For taller structures, it is particularly crucial to consider the possibility of lightning strikes to the sides of the building, especially at points, corners, and edges of surfaces.

Additionally, air terminal systems actively intercept direct lightning strikes and safely channel their energy to the ground, serving as a crucial component of the Lightning Protection System (LPS) that prevents damage to structures and equipment.

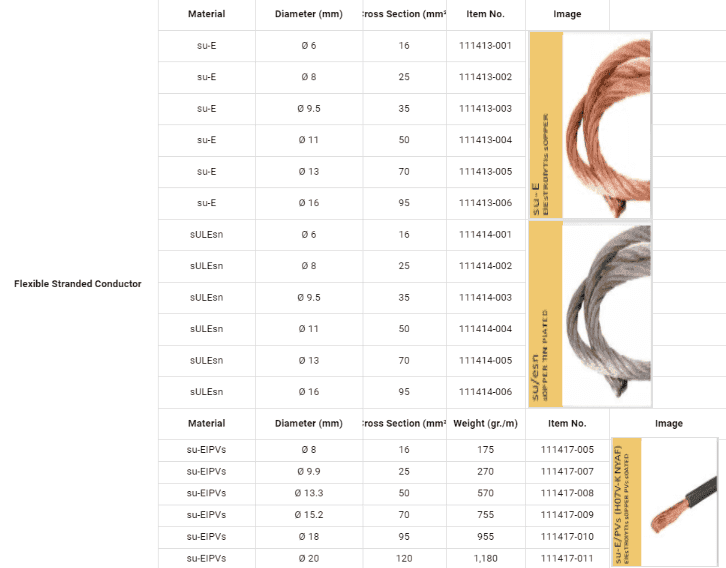

- Down Conductor Method – In the Down Conductor Method, install down conductors straight. Vertical to create the shortest and most direct path to earth. Ensure that down conductors, as much as possible, continue directly from the air-termination conductors. Construct down conductors using materials with high conductivity, such as copper or aluminum, and securely fasten them to the structure to withstand lightning forces. Bond the conductors to all metallic elements of the structure, including HVAC units, piping, and steel frameworks, to prevent step and touch voltages.

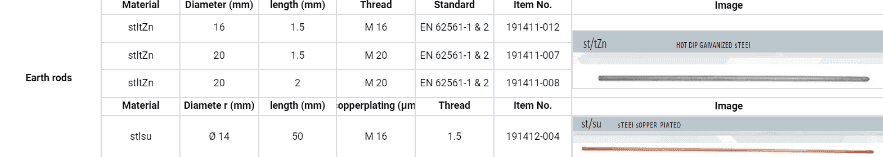

- Earth Termination Method- For the dispersion of the lightning current into the ground, minimizing any potentially dangerous overvoltages. The shape and dimensions of the earth-termination system are important. A low earthing resistance (less than 10 Ω) is recommended.

- Equipotential Bonding Method– This method involves connecting all metallic parts of a structure (for example- water pipes, gas pipes, and other conductive elements) to the Lightning Protection system. The reason for this type of connection is any potential difference between these parts. The lightning protection system is minimized, reducing the risk of electrical shock and damage.

Industrial Surge Protection

By installing a surge protection device (SPD) in your facility, you can easily avoid this catastrophe. Investing in surge and lightning protection is a wise decision that quickly proves its value.

It not only protects your equipment but also ensures your business remains operational and your commitments to clients are met.

However, there’s a hidden danger known as surge (or “transient overvoltage”) that poses a significant threat.

This phenomenon causes billions of dollars in equipment damage and operational downtime each year and in some cases. It can even endanger the lives of employees when transient overvoltage occurs.

What is Surge?

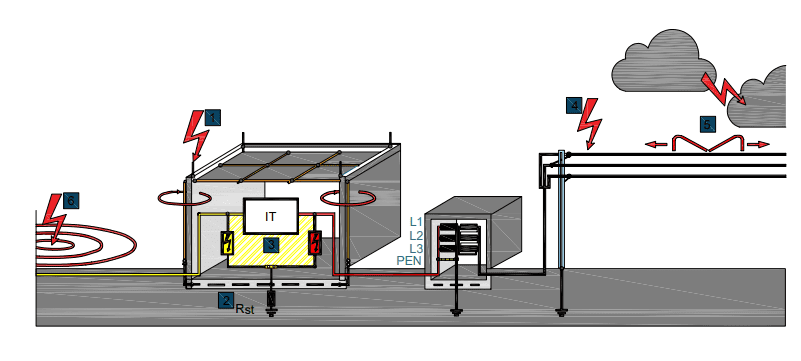

A surge is a transient overvoltage, depicted in the above diagram as a brief spike, lasting for only a millisecond or microsecond. This surge represents a voltage that exceeds the normal operating level. Protecting our devices from such surges is essential. Transient overvoltages are among the leading causes of damage in electrical systems.

These surges primarily occur due to lightning strikes or switching operations but can also result from other factors such as:

- Electrostatic discharge

- Arcing in large electric machines

- Power supply fluctuations

- Ground faults or short circuits

- Triggering of fuses

- Parallel installation of energy and control systems

Regardless of your business’s size, investing in a surge protection device is crucial. Such devices play a significant role in industrial settings, and selecting the right specifications ensures that your operations remain safe and uninterrupted.

suppressor Surge Protection Device (SPD), formerly known as a transient Voltage Surge suppressor (TVSS), is engineered to shield electrical systems and equipment from surge events by regulating transient voltages and redirecting surge currents. In the industrial context, SPDs are specifically crafted to protect machinery and systems within factory environments. These industrial surge protection devices are usually installed in a panel and mounted on a DIN rail. Ensuring robust protection for critical equipment in industrial settings.

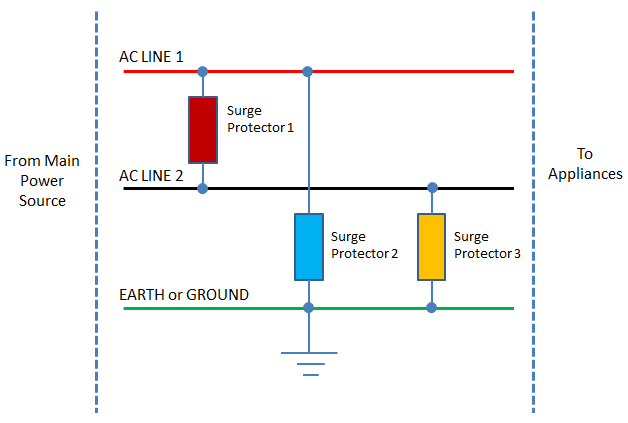

Under normal operating conditions with no over-voltage present, a surge protection device (SPD) has no impact on the system it’s installed in. It functions as an open circuit, maintaining isolation between the active conductors and the earth.

When an over-voltage occurs, the SPD activates and channels the excess current back to its source or to the ground. At this point, the SPD behaves like a closed circuit, effectively short-circuiting the over-voltage and reducing it to a safe level for the connected electrical equipment.

The surge protector reverts to its original impedance and resumes its open circuit state once it has managed and dissipated the overvoltage.

AC Surge Protector Types for Industrial Sites

The equipment in your manufacturing facilities is susceptible to damage from lightning and switching surges. Implementing a professional strategy for lightning and surge protection will ensure the longevity and reliability of your industrial sites.

Surge protective devices are classified according to their standards. The table below explains this in greater detail.

| SPD Type | Description | Waveform | Characteristics |

| Type 1 | Surge protective devices that can discharge partial lightning current | Typical waveform 10/350μs | Usually employs spark gap technology |

| Type 2 | Surge protective devices that can prevent the spread of overvoltage in electrical installations and protect connected equipment | Characterized by an 8/20μs current wave | Usually employs metal oxide varistor (MOV) technology |

| Type 3 | Surge protective devices that must only be installed as a supplement to Type 2 devices in the vicinity of sensitive loads | Characterized by a combination of voltage waves (1.2/50μs) and current waves (8/20μs) | Low discharge capacity |

Surge Protection Device Wiring Diagram

Surge protection works by absorbing overvoltage by clamping the transient voltage, as shown in the diagram. Manufacturers frequently use such SPDs as built-in surge protectors. SPD 1 should typically be sufficient to pass standard surge requirements, yet SPD 2 and 3 are necessary for higher surge voltage requirements.

LPES has a wide range of surge protection devices for power and telecom as per their application.

Main distribution board

LPESventil and LPESshield series For protecting the power supply at the main incoming supply. Spark-gap-based combined arrester with integrated lightning current-carrying backup fuse. And low voltage protection level UP ≤ 1.5 kV (including backup fuse). Extinction of mains follows currents up to 100 kArms. For protecting the power supply of low-voltage consumer’s installations. Multipole type 1 + type 2 spark-gap-based combined arrester according to EN 61643-11

Sub-distribution board

LPESguard series For protection, the Type 2 surge arrester has an integrated MOV and gas discharge tube for AC and DC.

Protection of terminal devices

LPES mounts the type 3 LPESflex arrester directly at the terminal device. Moreover, it is ideal for installation in cable ducts and installation boxes. However, other places of installation are also possible.

Information & Technology

LPESrapid series: This surge protection device series for LSA technology (LSA-PLUS/LSA+) is a flexibly combinable system of lightning current and surge arresters for telecommunication systems and measuring and control applications.

Moreover, the LPESvario series offers a compact combined arrester for security surveillance systems with BNC and RJ45 connectors.

Additionally, the LPESpatch series provides a universal surge protection device for GBit Ethernet applications. Power over Ethernet (IEEE 802.3-compliant up to PoE++/4PPoE) and similar applications in structured cabling systems up to class E.

LPESductor Series protects communication and measuring devices of automation/heating systems. The plug-in module, including the base part. Directly mounts onto the electronic component of heating, air-conditioning systems, or heat pumps that need protection.

The issue of surge protection against industrial surges is complex, requiring careful consideration of multiple contributing factors. LPES engineers its surge protection modules to effectively divert surges. And currents to the ground, safeguarding both personnel and machinery from potential adverse effects. Furthermore, our comprehensive product range offers power surge protection solutions tailored to a variety of applications.

We are pleased to share our expertise to help you select the appropriate type of industrial surge protection that ensures the safety and integrity of your assets. Please do not hesitate to contact us for assistance.