Lightning and Surge Protection for Commercial Buildings

Lightning and surge protection for commercial buildings is essential for safeguarding these structures from the detrimental effects of lightning strikes and electrical surges. Furthermore, commercial buildings function as hubs for professional activities and vital spaces where people regularly spend considerable time.

One major contributor to energy consumption in commercial structures is lighting. Transitioning to LED fixtures and energy-efficient lighting can significantly reduce energy usage. Additionally, employing smart lighting systems that detect occupancy and natural light can further optimize energy efficiency. As a result, these measures not only lower energy costs but also contribute to a more sustainable environment.

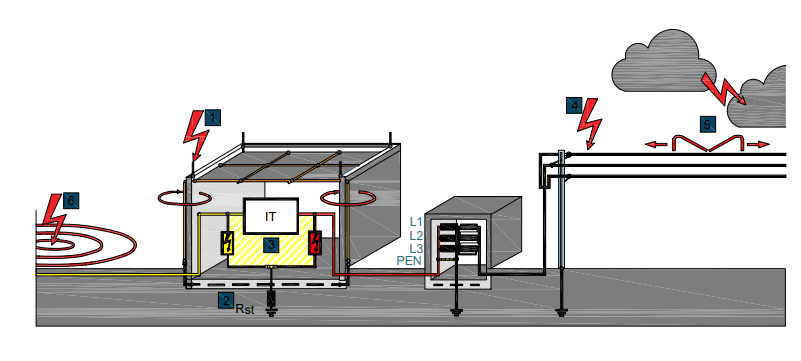

Lightning strikes on or near commercial buildings can severely impact the structure, occupants, and essential equipment. To reduce these risks, installing comprehensive lightning and surge protection is essential, combining external lightning protection with internal surge protection per IEC 62305 guidelines.

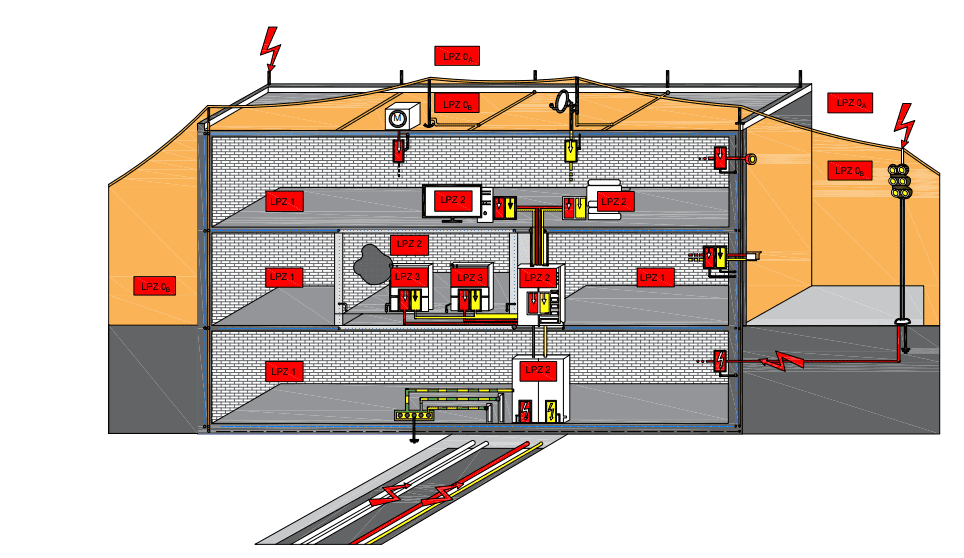

Understanding Lightning Protection Zones (LPZ)

According to IEC 62305, commercial buildings are classified into various Lightning Protection Zones (LPZ):

LPZ 2 to n: Surge currents may be further restricted with additional protective measures and spatial shielding.

LPZ OA: Exposed to direct lightning flashes and full electromagnetic fields. Internal systems may experience full or partial surge currents.

LPZ OB: Protected against direct lightning flashes, but internal systems may still face partial surge currents.

LPZ 1: Surge currents are limited by current sharing and isolation interfaces. Spatial shielding may help attenuate the electromagnetic field.

External Lightning Protection for Commercial Buildings

Lightning and surge protection for commercial buildings involves various methodologies:

- Air Termination Method:

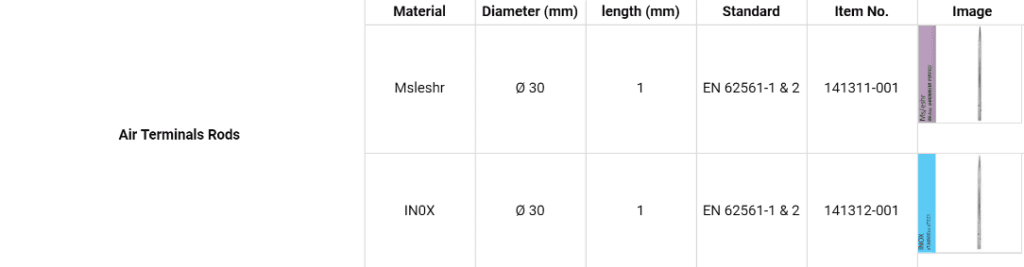

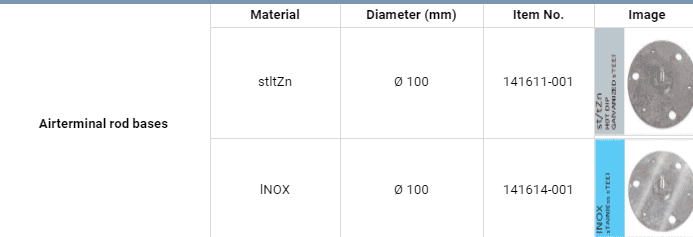

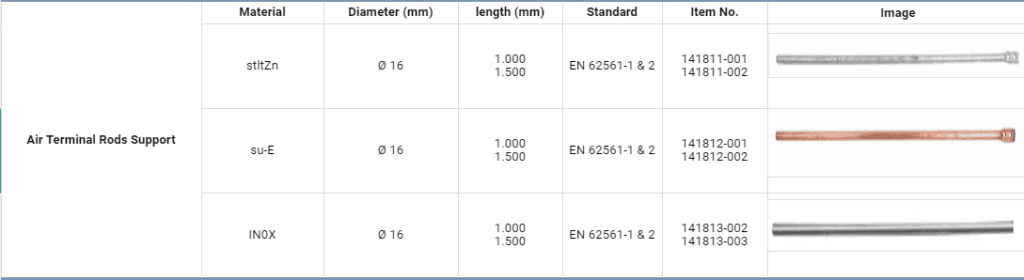

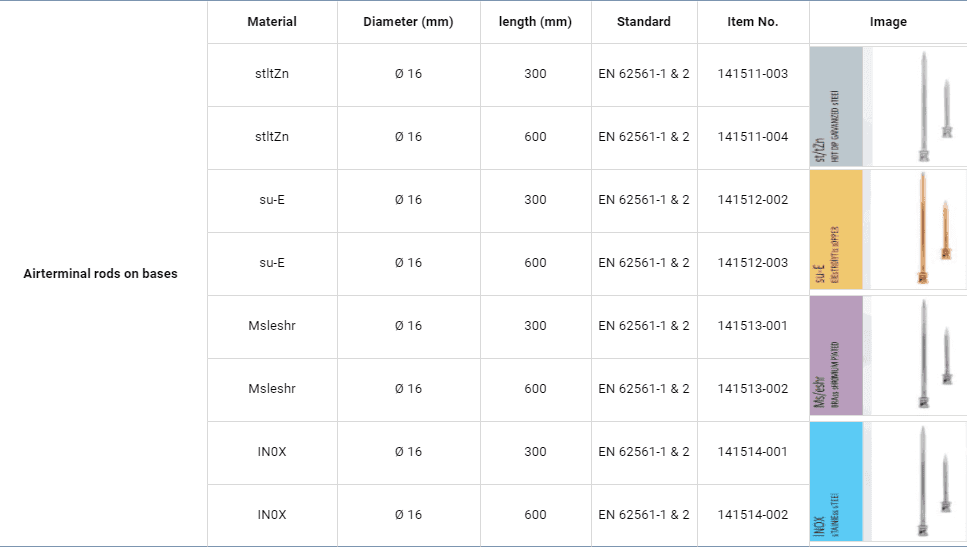

According to the standard, an external LPS must position rods, mesh conductors, or wires to intercept lightning across all air-termination systems.

As per the building height and lightning protection level. For the taller structures, lightning flashes to the side of the buildings may occur, mainly to the points, corners, and edges of surfaces.

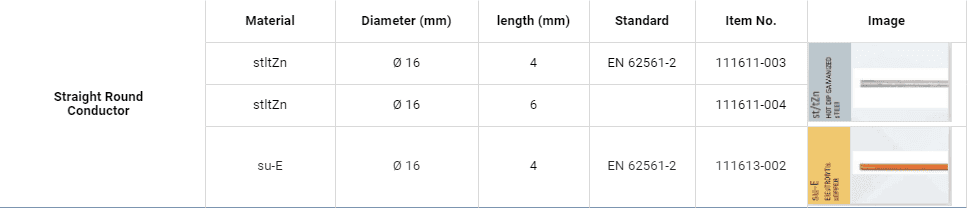

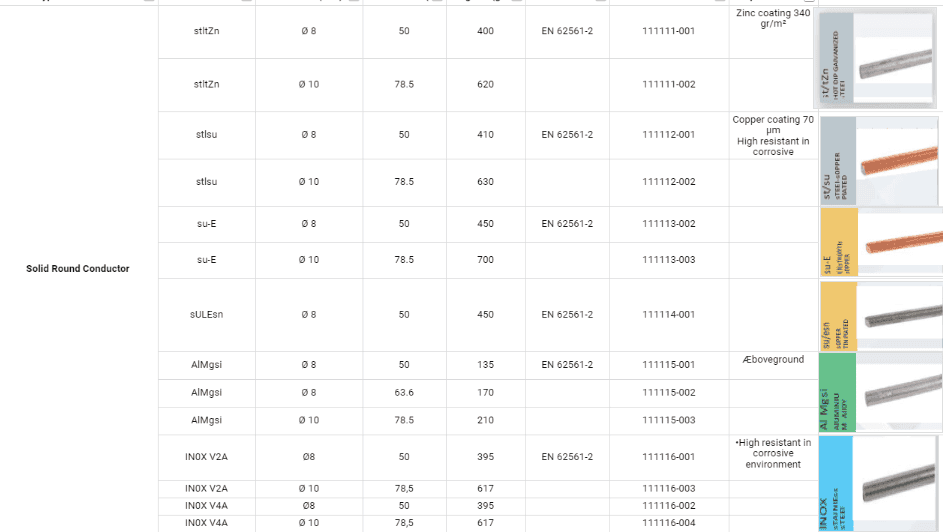

- Down conductor method: Down-conductors shall be installed straight and vertically such that they provide the shortest

and most direct path to Earth. The down-conductors shall be installed so that, as far as practicable, they form a direct continuation of the air-termination conductors.

- Earth Termination Method: For the dispersion of the lightning current into the ground, minimizing any potentially dangerous overvoltages, the shape and dimensions of the earth-termination system are important. We recommend a low earthing resistance of less than 10 Ω.

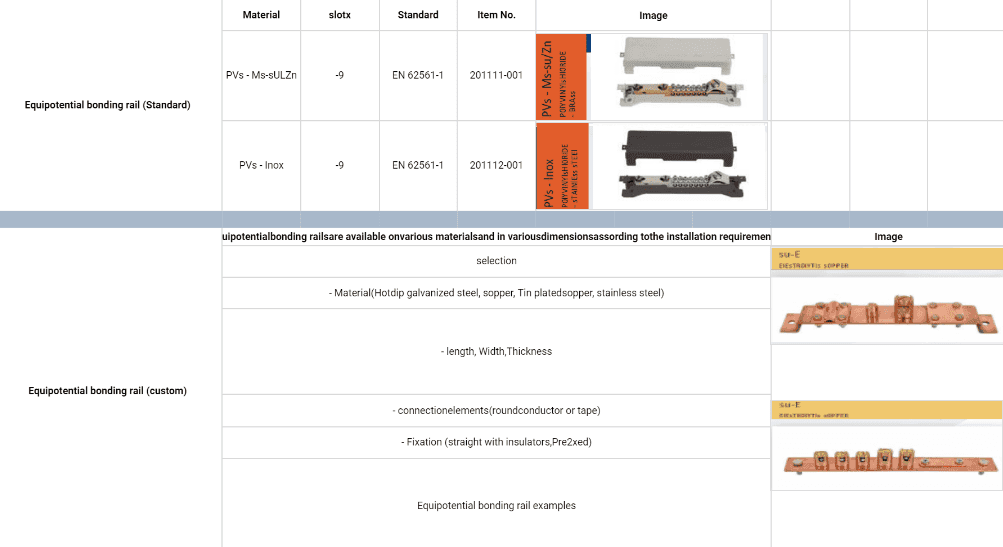

- Equipotential Bonding Method: This method involves connecting all metallic parts of a structure (for example- water pipes, gas pipes, and other conductive elements) to the Lightning Protection system. This connection minimizes potential differences with the lightning protection system, thereby reducing the risk of electrical shock and damage.

Internal Surge Protection:

By installing a surge protection device (SPD) in the facility, we can easily avoid this disaster. Furthermore, investing in surge and lightning protection is a wise decision that quickly proves its value. Not only does it protect your equipment, but it also ensures your business remains operational and that your commitments to clients are met. Consequently, prioritizing surge protection ultimately enhances your overall business reliability.

In today’s tech-driven world, businesses rely on electrical equipment for functions like communication and payment processing. However, surges or transient overvoltage pose serious risks. These surges cause billions in equipment damage, and downtime, and, in extreme cases, endanger employee safety.

What is Surge?

A surge is a transient overvoltage, shown as a brief spike in the diagram, lasting just a millisecond or microsecond.

- Electrostatic discharge

- Arcing in large electric machines

- Power supply fluctuations

- Ground faults or short circuits

- Triggering of fuses

- Parallel installation of energy and control systems

Regardless of your business’s size, investing in a surge protection device is crucial. Moreover, such devices play a significant role in industrial settings, and selecting the right specifications ensures that your operations remain safe and uninterrupted. Consequently, prioritizing surge protection can prevent costly downtime and equipment damage.

Engineers design a surge protection device (SPD), formerly known as a transient voltage surge suppressor (TVSS), to shield electrical systems and equipment from surge events by regulating transient voltages and redirecting surge currents. In the industrial context, manufacturers specifically craft SPDs to protect machinery and systems within factory environments. Typically, installers mount these industrial surge protection devices in a panel on a DIN rail, ensuring robust protection for critical equipment in industrial settings. Under normal operating conditions with no overvoltage present, a surge protection device (SPD) does not affect the system in which it is installed.

When an overvoltage occurs, the SPD activates and channels the excess current back to its source or the ground. At this point, the SPD functions as a closed circuit, effectively short-circuiting the overvoltage and reducing it to a safe level. Consequently, this process ensures the safety of the connected electrical equipment during surge events.

Once the system manages and dissipates the overvoltage, the surge protector reverts to its original impedance and resumes its open circuit state.

Surge protective devices are classified according to their standards. The table below explains this in greater detail.

| SPD Type | Description | Waveform | Characteristics |

| Type 1 | Surge protective devices that can discharge partial lightning current | Typical waveform 10/350μs | Usually employs spark gap technology |

| Type 2 | Surge protective devices that can prevent the spread of overvoltage in electrical installations and protect connected equipment | Characterized by an 8/20μs current wave | Usually employs metal oxide varistor (MOV) technology |

| Type 3 | Surge protective devices that must only be installed as a supplement to Type 2 devices in the vicinity of sensitive loads | Characterized by a combination of voltage waves (1.2/50μs) and current waves (8/20μs) | Low discharge capacity |

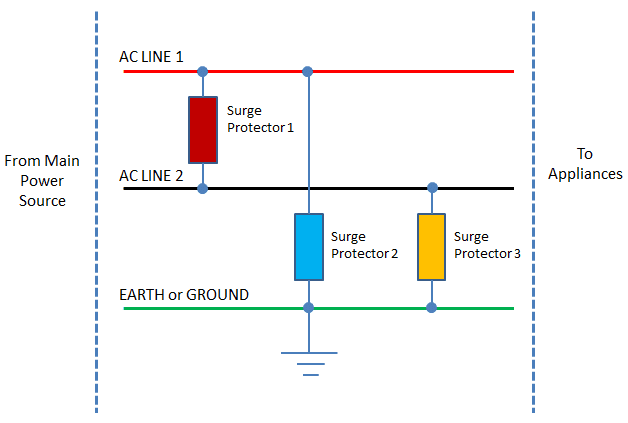

Surge Protection Device Wiring Diagram

Surge protection effectively absorbs overvoltage by clamping transient voltage, as illustrated in the diagram. Furthermore, manufacturers often use surge protection devices (SPDs) as built-in protectors, enhancing overall reliability. Consequently, this integration prevents damage to sensitive equipment and ensures uninterrupted operation. Additionally, utilizing SPDs contributes to longer equipment lifespans, offering both immediate and long-term benefits for users.

LPES has a wide range of surge protection devices for power and telecom as per their application.

Main distribution board

The LPESventil and LPESshield series protect the power supply at the main incoming supply. Additionally, they feature a spark-gap-based combined arrester with an integrated lightning current carrying backup fuse and low voltage protection level UP ≤ 1.5 kV. Moreover, they extinguish mains and follow currents up to 100 kA. Furthermore, these devices protect the power supply of low-voltage consumer installations with a multipole type 1 + type 2 design according to EN 61643-11.

Sub-distribution board

LPESguard series For protection, the Type 2 surge arrester has an integrated MOV and gas discharge tube for AC and DC.

Protection of terminal devices

LPESflex: The type 3 LPESflex arrester is mounted directly at the terminal device. It is ideal for installation in cable ducts and installation boxes. Other places of installation are possible.

Information & Technology

LPESrapid series This SPD series for LSA technology offers a flexible system of lightning current and surge arresters for telecom and control applications.

LPESvario series compact combined arrester for a security surveillance system with BNC and RJ45 connectors.

LPESpatch series Universal surge protection device for GBit Ethernet applications, Power over Ethernet (IEEE 802.3-compliant up to PoE++/4PPoE), and similar applications in structured cabling systems up to class E.

LPESductor Series protects communication and measuring devices of automation/heating systems. The installation team mounts the base and module directly onto electronic components of heating, air conditioning, or heat pumps.

The issue of surge protection for commercial buildings is complex; thus, it requires careful consideration of multiple factors. In this context, LPES designs surge modules that safely divert surges to the ground, protecting personnel and machinery.