Fire Alarm Surge Protection: Safety Against Lightning & Surges

Fire alarm surge protection is crucial for preventing fire incidents in buildings. Therefore, according to the NFPA 780 Code, “surge protection must be installed at all electric service entrances, at the entrances of communication systems. And where these systems exit the building to supply another structure with a cable run exceeding 100 feet (30 m).”

Why Surge Protection Matters

Fire can cause severe damage to public buildings, potentially leading to significant losses in material, life, data, and network connectivity. Therefore, fire alarm systems require robust protection against lightning and surges to ensure uninterrupted operation. Fortunately, our surge protection devices (SPDs) provide a comprehensive solution for safeguarding fire alarm systems. Specifically, a surge is a brief overvoltage that exceeds normal levels; consequently, it can pose serious risks to equipment.

Components of a Fire Alarm System

A complete fire alarm system includes:

- Fire Alarm Control Panel (FACP)

- Detectors

- Displays

- Manual call points

- Sub-control panels

- Operating devices

For these systems to function seamlessly, protection against lightning-induced sparking or surges is vital, even when external lightning protection is in place.

Types of Sparking

- Thermal Sparking: This occurs when a high current crosses joints between conductive materials. Often due to high current density and low interface pressure.

- Voltage Sparking: Happens when current takes convoluted paths, causing voltage-induced loops that exceed breakdown voltages.

Protecting Your Fire Alarm System

Surge Protection Devices (SPDs) are essential to prevent failures in detectors, alarms, and monitoring panels. Moreover, electronic components in alarm systems operate on low voltage, which makes them particularly vulnerable to surges. Therefore, proper installation of SPDs is crucial, as it ensures that your fire alarm system remains operational, even during lightning events.

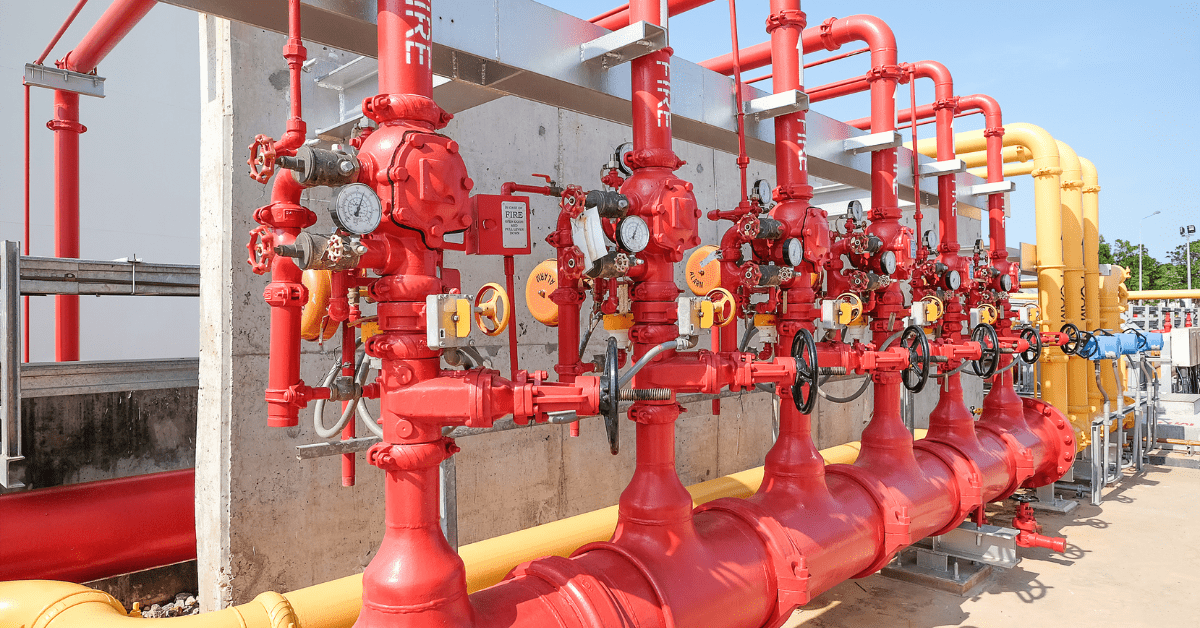

Figure –

Small surges, even when unnoticed, can cause significant damage to safety systems. Moreover, this damage is often difficult to detect, which makes it a hidden but serious threat. In fact, according to the Insurance Information Bureau of India (IIB), electrical surges and overvoltage are among the top causes of damage to electronic equipment. As a result, these incidents lead to financial losses in the billions.

The Growing Need for Surge Protection in India’s Thunderstorm-Prone Environment

In India, where thunderstorms and electrical storms are common, the risk of electrical surges becomes even more pronounced. Specifically, with an estimated 6,000–10,000 thunderstorms occurring annually, the frequency and intensity of these storms can lead to unexpected overvoltage situations. Furthermore, the Indian Meteorological Department (IMD) reported over 2 million lightning strikes across the country in recent years. This statistic emphasizes the urgency for businesses to address surge protection.

Moreover, the financial impact is substantial. A study reveals that electrical failures, including those caused by surges, account for approximately 30% of insurance claims. Related to electronic equipment in India. Consequently, this statistic highlights the importance of investing in robust surge protection strategies. Particularly in industrial and commercial settings where electronic systems are integral to operations.

For the complete fire alarm system with monitoring and alarm devices. LPES specifically recommends the following SPDs based on their location. This approach ensures the smooth operation of the fire alarm system. And keeps building occupants free from the fear of fire incidents.

Figure: SPD direct/indirect shield earthing with LPESductor for cable across several buildings with different earth potentials.

Even with proper equipotential bonding, improper cable routing can significantly compromise protection or damage the connected device. Specifically, if the unprotected line before the surge protection device (SPD) and the protected line after the SPD are not kept spatially separated or shielded, electromagnetic fields can easily couple interference impulses into the protected side. To effectively address these concerns, IEC 60364-4-44 outlines essential installation guidelines, which include avoiding cable loops, keeping power and IT cables separate, and maintaining a clear separation between protected and unprotected cables. Moreover, Figure 5 illustrates these critical installation techniques.

Wiring during SPD Installation

The wiring of the surge protection device in the circuit should be proper and adhere to established standards. Notably, incorrect cable routing can lead to increased electromagnetic induction, which may adversely affect the protective element and even potentially cause the failure of the end device. Therefore, it is crucial to follow best practices during installation to ensure optimal performance and reliability.

Conclusion

Proven Experience in Fire Alarm Surge Protection:

LPES has gained a decade of experience in lightning and earthing protection, completing over 70 projects. Consequently, this acquired experience is reflected in our fire alarm surge protection product specialization and selection.

Essential Role of Fire Alarm Surge Protection Systems:

In any building, fire alarm surge protection plays an important role in safeguarding such a high-value system. Moreover, fire alarm systems are designed to detect and report hazardous situations within monitored areas. As critical safety devices, they are held to high standards for reliable operation and the prevention of false alarms.

Ensuring Stability with Effective Surge Protection:

Therefore, fire alarm surge protection against overvoltage from lightning strikes and electrical switching is essential to ensure system stability. In addition, regulations in many countries not only mandate but also emphasize the importance of implementing appropriate fire alarm surge protection measures.

Optimal Performance with LPES Surge Protection Devices:

Effective defense against lightning and surges requires coordinated external and internal protection systems, along with suitable surge protection devices (SPDs). Consequently, this approach ensures optimal system performance and safety. Specifically, LPES recommends using TELECOM SPDs to connect with the fire protection system. And furthermore, Power SPDs should be utilized for the end devices.

The importance of uninterrupted fire alarm system operation:

Ultimately, we want these facilities to operate smoothly without issues such as lightning and surges. Fire poses a serious threat to public buildings. Therefore, to prevent losses in materials and lives, the fire alarm system must function without interruption.

LPESflex D-230RM

| Type | LPESflex D 230 RM |

| Nominal a.c. voltage [UN] | 230V |

| Rated voltage (max. continuous a.c. voltage) [ Uc ] | 320V |

| Rated voltage (max. continuous d.c. voltage) [UC] | 320V |

| Nominal load current [IL] | 16A |

| Nominal discharge current (8/20) (L-N) [In] | 3kA |

| Nominal discharge current (8/20) (L+N-PE) [In] | 5kA |

| Combination wave (L-N) [ U Oc ] | 6kV |

| Combination wave (L+N-PE) [ U Oc ] | 10kV |

| Voltage protection level (L-N) [Up] | ≤1.15kV |

| Voltage protection level (L/N-PE) [Up] | ≤1.5kV |

| Response time (L-N) [tA] | ≤25ns |

| Response time (L/N-PE) [tA] | < 100ns |

| Max. backup fuse | 16A gL/gG |

| Short-circuit withstand capability at max. backup fuse | 6kArms |

| Operating temperature range [Tu] | -40°C…+80°C |

| Cross-sectional area | 0.5mm2 ~ 6mm2 solid /4mm2 flexible |

| Mounting on | 35mm DIN rail |

| Enclosure material | Purple thermoplastic, UL94-V0 |

| Dimension | 1.5 mods |

| Test standards | IEC 61643-11; GB 18802.11; YD/T 1235.1 |

| Certification | CE (LVD, EMC) |

| Type of remote signaling contact | Break contact |

| Switching capacity a.c. | 250V/0.5A |

| Switching capacity d.c. | 250V/0.1A; 125V/0.2A; 75V/0.5A |

| Cross-sectional area for remote signaling contact | Max. 1.5mm2 solid/flexible |

LPESductor LD 5/4M

| Type | LPESductor LD 5/4M |

| Nominal voltage [ UN ] | 5V |

| Rated voltage (max. continuous d.c. voltage) [ UC ] | 6V |

| Rated voltage (max. continuous a.c. voltage) [ UC ] | 4.2V |

| Nominal current [ IL ] I ] | 1.0A |

| Lightning impulse current (10/350) [ Iimp ] | 2.5kA |

| Lightning impulse current (10/350) (total) [ Iimp ] | 10kA |

| Nominal discharge current (8/20) [ IN ] I ] | 10kA |

| Nominal discharge current (8/20) (total) [ IN ] | 20kA |

| Voltage protection level at I (line-line) [ U P ] | ≤ 29V |

| Voltage protection level at I (line-PG) [ UP ] | ≤ 26V |

| Voltage protection level at 1kV/μs (line-line) [ UP ] | ≤ 18V |

| Voltage protection level at 1kV/μs (line-PG) [ UP ] | ≤ 9V |

| Bandwidth (line-PG) [ fG] | 1.2MHz |

| Series impedance per line [ R ] | 1 .0Ω |

| Capacitance (line-line) [ C ] | ≤ 2.7nF |

| Capacitance (line-PG) [ C ] | ≤ 5.4nF |

| Response time (line-line) [ t A ] | ≤ 1ns |

| Response time (line-PG) [ tA ] | ≤ 1ns |

| Operating temperature range | -40°C…+80°C |

| Cross-sectional area | 0.08mm2 ~4mm2 solid 2.5mm2/solid flexible |

| Mounting on | 35mm DIN rail |

| Enclosure material | Orange thermoplastic, UL94-V0 |

| Test standards | IEC 61643-21; GB 18802.21; YD/T 1542 |

| Certification | CE (LVD, EMC) |

LPESductor LD 48/4M

| Type | LPESductor LD 48/4M |

| Nominal voltage [ UN ] | 48V |

| Rated voltage (max. continuous d.c. voltage) [ UC ] | 54V |

| Rated voltage (max. continuous a.c. voltage) [ UC ] | 38.2V |

| Nominal current [ IL ] I ] | 0.75A |

| Lightning impulse current (10/350) [ Iimp ] | 2.5kA |

| Lightning impulse current (10/350) (total) [ Iimp ] | 10kA |

| Nominal discharge current (8/20) [ IN ] I ] | 10kA |

| Nominal discharge current (8/20) (total) [ IN ] | 20kA |

| Voltage protection level at I (line-line) [ U P ] | ≤ 160V |

| Voltage protection level at I (line-PG) [ UP ] | ≤ 95V |

| Voltage protection level at 1kV/μs (line-line) [ UP ] | ≤ 140V |

| Voltage protection level at 1kV/μs (line-PG) [ UP ] | ≤ 70V |

| Bandwidth (line-PG) [ fG] | 8 .5MHz |

| Series impedance per line [ R ] | 1 .8Ω |

| Capacitance (line-line) [ C ] | ≤ 0.35nF |

| Capacitance (line-PG) [ C ] | ≤ 0.7nF |

| Response time (line-line) [ t A ] | ≤ 1ns |

| Response time (line-PG) [ tA ] | ≤ 1ns |

| Operating temperature range | -40°C…+80°C |

| Cross-sectional area | 0.08mm2 ~4mm2 solid 2.5mm2/solid flexible |

| Mounting on | 35mm DIN rail |

| Enclosure material | Orange thermoplastic, UL94-V0 |

| Test standards | IEC 61643-21; GB 18802.21; YD/T 1542 |

| Certification | CE (LVD, EMC) |

LPESductor LD 24/4M

| Type | LPESductor LD 24/4M |

| Nominal voltage [ UN ] | 24V |

| Rated voltage (max. continuous d.c. voltage) [ UC ] | 33V |

| Rated voltage (max. continuous a.c. voltage) [ UC ] | 23.2V |

| Nominal current [ IL ] I ] | 0.75A |

| Lightning impulse current (10/350) [ Iimp ] | 2.5kA |

| Lightning impulse current (10/350) (total) [ Iimp ] | 10kA |

| Nominal discharge current (8/20) [ IN ] I ] | 10kA |

| Nominal discharge current (8/20) (total) [ IN ] | 20kA |

| Voltage protection level at I (line-line) [ U P ] | ≤ 100V |

| Voltage protection level at I (line-PG) [ UP ] | ≤ 65V |

| Voltage protection level at 1kV/μs (line-line) [ UP ] | ≤ 90V |

| Voltage protection level at 1kV/μs (line-PG) [ UP ] | ≤ 45V |

| Bandwidth (line-PG) [ fG] | 6.5MHz |

| Series impedance per line [ R ] | 1.8Ω |

| Capacitance (line-line) [ C ] | ≤0.5nF |

| Capacitance (line-PG) [ C ] | ≤ 1.0nF |

| Response time (line-line) [ t A ] | ≤ 1ns |

| Response time (line-PG) [ tA ] | ≤ 1ns |

| Operating temperature range | -40°C…+80°C |

| Cross-sectional area | 0.08mm2 ~ 4mm2 /2.5mm2 solid flexible |

| Mounting on | 35mm DIN rail |

| Enclosure material | Orange thermoplastic, UL94-V0 |

| Test standards | IEC 61643-21; GB 18802.21; YD/T 1542 |

| Certification | CE (LVD, EMC) |

LPESgate G SMA

| Type | LPESgate G SMA |

| Rated voltage (max. continuous d.c. voltage) [ UC ] | 250V |

| Nominal current [ IL ] | 3.5A |

| Lightning impulse current (10/350) [ Iimp ] | 1.0kA |

| Nominal discharge current (8/20) [ In ] | 5kA |

| Max. discharge current (8/20) [ Imax ] | 10kA |

| Voltage protection level at Imax [Up ] | ≤ 700V |

| Frequency range [ F ] | 0-3.0GHz |

| Max. output power [ P ] | 500W |

| Return loss [ aR ] | ≥ 20dB |

| Insertion loss [ aE] | ≤ 0.2dB |

| Characteristic impedance [ Z ] | 50Ω |

| Operating temperature range | -40°C…+80°C |

| Earthing via | SMA socket/plug |

| Connection input/output | Outgoing connecting port |

| Test standards | IEC 61643-21; GB 18802.21; YD/T 1542 |

| Certification | CE (LVD, EMC) |

LPESrapid LSA 10G 110

| Type | LPESrapid LSA 10G 110 |

| Nominal voltage [ UN ] | 110V |

| Rated voltage (max. continuous d.c. voltage) [ UC ] | 180V |

| Rated voltage (max. continuous a.c. voltage) [ UC ] | 127V |

| Lightning impulse current (10/350) [ Iimp ] | 1KA |

| Nominal discharge current (8/20) (per line) [ In ] | 10KA |

| Voltage protection level at 1kV/μs (line-line) [ Up ] | ≤ 600V |

| Voltage protection level at 1kV/μs (line-PG) [ Up ] | ≤ 600V |

| Capacitance (line-line) [ C ] | ≤ 5pF |

| Capacitance (line-PG) [ C ] | ≤ 5pF |

| Response time (line-line) [ tA ] | ≤ 100ns |

| Response time (line-PG) [ tA ] | ≤ 100ns |

| Operating temperature range | -40°C…+80°C |

| Pluggable into | LSA-PLUS disconnection and terminal blocks |

| Earthing via | Mounting frame |

| Enclosure material | Gray thermoplastic, UL94-V0 |

| Test standards | CE (LVD, EMC) |

| Certification | IEC 61643-21; GB 18802.21; YD/T 1542 |